Individuality of movement

With castors it is just like with people – there are various types and characteristics.

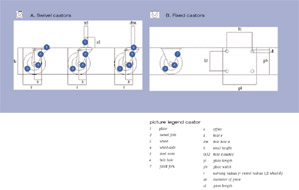

We distinguish between two types of castors: Swivel castors can swivel on a vertical axis. In this way machines and equipment can be manoeuvred. In order to make it possible for the steering fork to swivel, in this type of castor, the steering fork is connected by means of a swivel bearing with the fixing element mounted in a fixed position on the apparatus. The swivelling of the fork and so the manoeuvrability of the equipment is made easier by having the wheels contact with the floor offset horizontally from the axis of the swivel bearing. Furthermore, this so-called off-set improves the stability of the rolling behaviour when moving in a straight line.

Swivel castors are manufactured with or without brakes. Braked swivel castors enable, various modes such as wheel rotation, fork head rotation and direction, to be locked individually or collectively. Tested and proven fixing elements for swivel castors such as bolt-on plates, steel and plastic expanders for tube are available, and their attachment is made by means of screwing the required fixing into a blind tapped hole on the castor fork.

Fixed castors cannot swivel. They give equipment and machines a high degree of directional stability. With regard to the fixings, bolt on plates are usually used.